[ad_1]

I made some progress on the studio office area cabinets yesterday and it’s exciting to see the area coming together. I showed you the other day that I finished all the doors and drawer fronts. I installed several and took a picture so we could get an idea of what this finished area would look like. It still takes some imagination to figure it out, but here is my progress…

So after they were done, I had to remove all the doors and drawer fronts to work on the cabinet boxes and finish them. I started by adding 2″ x 2″ lumber to the left cabinet side to fill the space between the left cabinet and the wall. I attached this using screws (which I’m sure I didn’t need for my shelf placements) that I drilled through the shelf pin holes inside the cabinet and into the 2″ x 2″ wood. This 2″ x 2″ piece of wood gives me a surface to attach the final trim piece to later.

I did the same thing on the other sides of the cabinets. But on the other three sides, I attached two 2″ x 2″ pieces of wood, one flush with the front edge of the cabinet and the other toward the back, as these will be used to attach the plywood to cover the sides. Again, I attached these using wood screws screwed through the shelf pin holes inside the cabinet, through the cabinet and into the wood. But the most important part of this is making sure the front 2″ x 2″ piece is perfectly flush with the front edge of the IKEA cabinets.

I repeated the process on the other side…

Then I repeated the process once more on the outside of the right cabinet.

With those strips attached, I can attach a piece of plywood to the outside of the right cabinet. I attached it using 1.5-inch 16-gauge nails and I nailed it to 2″ x 2″ pieces of wood. You can see that I cut pieces of plywood slightly longer than the cabinet to give me something to attach the trim and crown molding to in the next step. And once again, I made sure the front edge of the plywood was perfectly (or as perfectly as possible) flush with the front edges of the 2″ x 2″ lumber and the front edge of the IKEA cabinets.

I decided to add sconces to the window side of each cabinet, before I attached the plywood panels I had to add junction boxes to them. I used shallow old work boxes for this so that they fit in the space between the plywood and the side of the Ikea cabinet. I don’t like having to cut the inside of an IKEA cabinet to fit a standard size junction box. I measured and marked where I wanted the box to go on the plywood panel, then used the box as a template to mark where to cut.

I made sure to get it right because I only had one chance at this. If I mess this up, I’ll have to cut a whole new piece of plywood.

I used my Dremel Multimax oscillating saw to cut the hole for the box. You can use a drill and jigsaw, or even a router. With the hole cut, I added my old work box, which was screwed to the plywood.

I forgot to take a picture of the junction box before standing the panel upright and running the wire through it, but you can still see it pretty clearly here. You may see old work junction boxes sitting on top of a surface (plasterboard, or in the case, plywood), making the box much easier to screw into. Newer work boxes sit behind the surface material (usually drywall), so they are not useful for a project like this.

I decided to use heavy duty extension cords (with a ground wire) to wire the scans. To use the extension cord, I had to use my wire cutters to cut this end.

I had to do the wiring before attaching the plywood panel to the cabinet. So I ran the wire behind the panel and through the junction box.

The other end of the cord came out at the bottom of the plywood panel…

You can see here that it runs directly behind the plywood and into the space between the cabinets.

Then using a 1-inch drill bit, I drilled a hole in the back spacer in that section and threaded the wire through that hole.

Then I ran the wire through this space behind the cabinets, but above the spacers / braces I used to attach the cabinets to the wall. I put a piece of scrap 2″ x 2″ wood on top of the cabinet where the countertop will eventually go so you can see how much space the wire has to travel through. This is a fairly large space (about 2″ x 1″), so you can see that nothing will restrict the wire once the countertop is in place.

Once the wire was in place, I was able to nail the plywood panel to the side of the cabinet.

At that point, here’s what the right bank of the cabinets looks like with 2″ x 2″ wood and plywood panels attached to both sides of the cabinets.

Check out one of the scones here. I couldn’t take a picture with the sconce in place, so you’ll have to imagine it on the side panel where the junction box is. And of course, I had to paint the sconces and gold leaf them to match the pendant lights on the wall.

In place of that side panel, I needed to complete the side panel on the left. From the right side the wire ran back under the window behind the cabinets.

Then I ran a second wire (the extension cord) along with that wire through the hole I drilled in that back spacer.

Then I ran them behind the plywood panel and through the junction box.

That second wire (extension cord) then ran behind the left cabinet and through this access panel I had to cut through the back of the center cabinet on the left side.

On the first extension cord, I cut off both ends so that I was left with wires. But on this second extension cord, I only cut off the end where the sconce is wired, but I left the end with a plug. Because once I finish wiring this outlet behind this access panel, the scones will be plugged into the outlet. I control the sconces with a remote-controlled outlet.

After those wires were run this way, I was able to nail the plywood panel.

So much progress! I’m so excited to get it all done. Working through the logistics of wiring those sconces took me a while to figure out, and it’s always a huge relief when a plan works out.

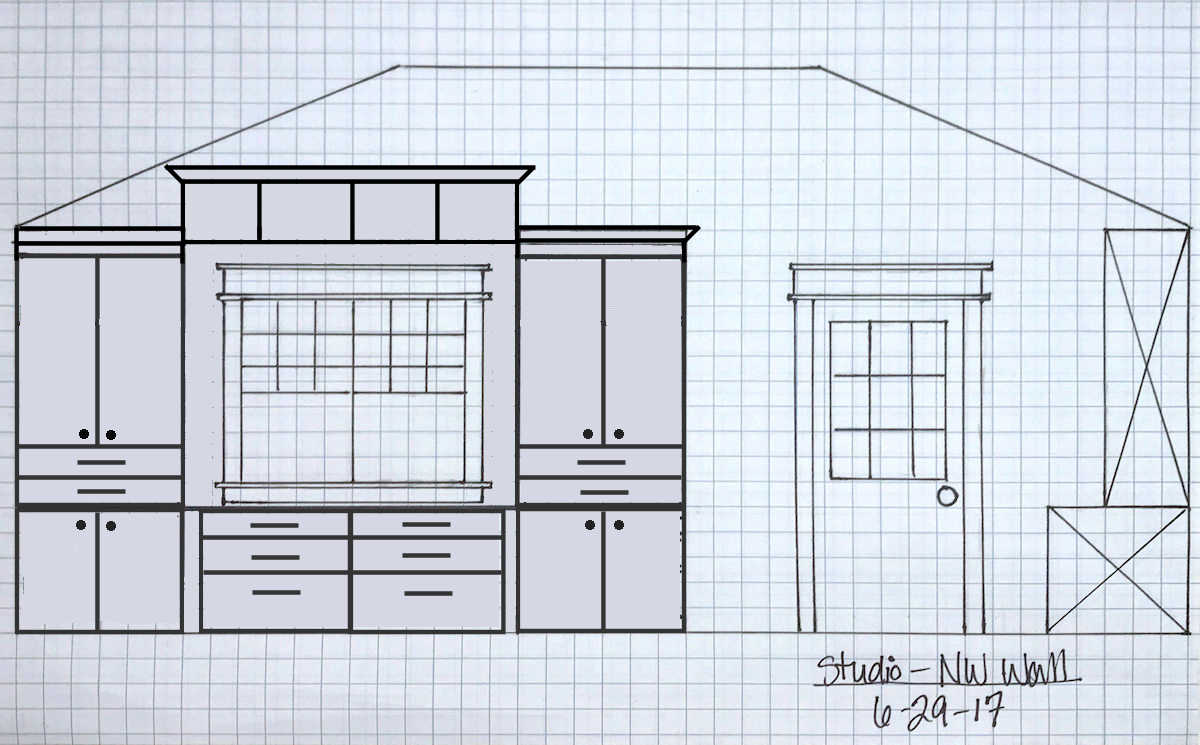

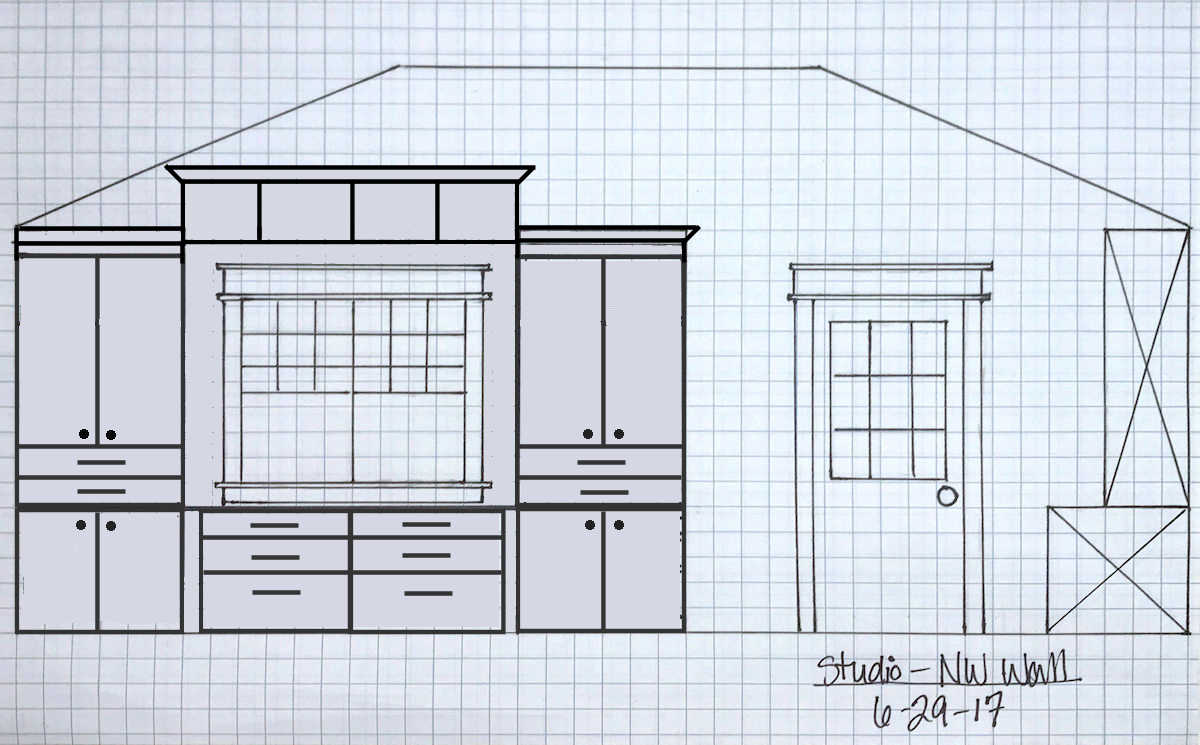

Today, I will work on the bridge with Cubis. If you remember, this vision…

I’m DIY, so I’m thinking of how I’m going to build a giant plywood bridge with cubbies, attach it to the side cabinets myself and raise it up. As a solo DIYer, these are the challenges I have to work on most often. But I think I figured it out. I guess we’ll all find out tomorrow if my plan worked out.

Addicted 2 Decorating shares my DIY and decorating journey as I renovate and decorate the 1948 Fixer Upper that my husband, Matt, and I purchased in 2013. Matt has MS and is unable to do physical activity, so I do most of the housework myself. You can learn more about me here.

[ad_2]